CENTROLLER

Most effective for saving labor and ensuringsafety in repair work inside furnaces

With recent advances in steel manufacturing technology for electric furnaces and the trend toward larger sizes, urgent need is to enhance efficiency and save labor in hotprocess repair work. Based on the development of an internal insulation spraying machine, our company has daveloped labor saving equipment for repair that may be used with a variety of furnaces.

This ASM furnace repair machine combines an internal insulation spraying machine and an automatic furnace repair machine and is based on our company's long experience and high technology.

This automatic machine for repair in hot furnaces can be operated safely and readily by remote control during the short periods between the steps of electric furnace operation.

Features of ASM furnace repair machine

1.Because the nozzle rotates at the center of a furnace,uniform spraying is assured over the entire circumference. And spraying/repair work in the vicinity of the working port,which has been difficult with conventional machines, can now be done easily and completely.

2.For repair at the peak of work during steel discharging,just one worker can handle hot,heavy-duty spraying work using the switch on the wireless pendent panel. In addition to nozzle operation,the wireless pendent panel is also used to turn on/off the spraying machine and increase/decrease the volume of water to be added, thus covering the entire spraying process.

3.Movement from the standby position to the center of the furnace is automatically made through wireless remote control.

4.For repair,the nozzle can be moved up and down while being rocated.In addition, local spraying is possible by moving the nozzle vertically and horizontally within a repair area.

5.Since the same spraying condition can be maintained over the entire circumference, a furnace is given an appropriate profile.Therefore,the power cost for dissolution will be reduced.

2.For repair at the peak of work during steel discharging,just one worker can handle hot,heavy-duty spraying work using the switch on the wireless pendent panel. In addition to nozzle operation,the wireless pendent panel is also used to turn on/off the spraying machine and increase/decrease the volume of water to be added, thus covering the entire spraying process.

3.Movement from the standby position to the center of the furnace is automatically made through wireless remote control.

4.For repair,the nozzle can be moved up and down while being rocated.In addition, local spraying is possible by moving the nozzle vertically and horizontally within a repair area.

5.Since the same spraying condition can be maintained over the entire circumference, a furnace is given an appropriate profile.Therefore,the power cost for dissolution will be reduced.

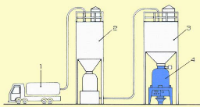

Equipment constitution

| 1 | CENTROLLER Automatic furnace repair unit | 7 | Spraying pipe |

| 2 | ROTEKTOR gunning machine | 8 | Tip nozzle |

| 3 | Switcher | 9 | Automatic line material hose |

| 4 | Pump unit | 10 | Manual spraying line material hose |

| 5 | Control panel | 11 | Spraying machine discharge port material hose |

| 6 | Handle-equipped mixing body for manual spraying |